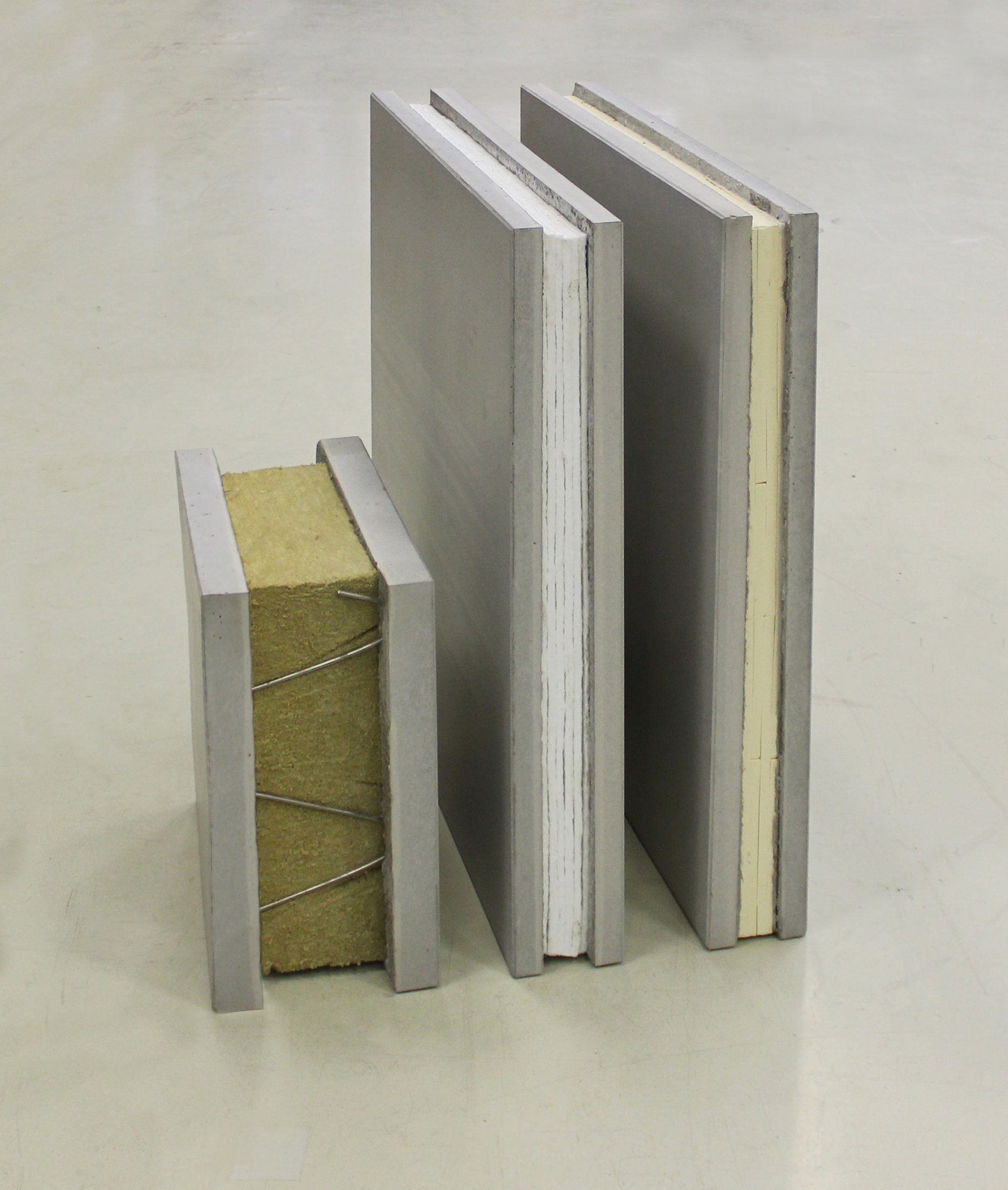

The climate change as well as surging energy prices create a pressing trend towards more energy efficiency in buildings to lower carbon dioxide emissions and energy consumption for heating and cooling. While essential from the sustainability point of view, the drive towards more energy efficiency has a well visible and undesirable impact on building aesthetics: Walls need to become increasingly thicker since layers of thermal insulation material such as mineral wool, expanded polystyrene or polyurethane foam need to keep up with the ever stricter energy-efficiency requirements. There is only so much performance available from these well-established thermal insulation materials.

This translates to ever thicker insulation layers and walls. However, as a downside, the resulting building designs become heavier in appearance. Windows become deeper and restrict the outside view. Altogether, an unpleasant, cumbersome aesthetic sensation is created.

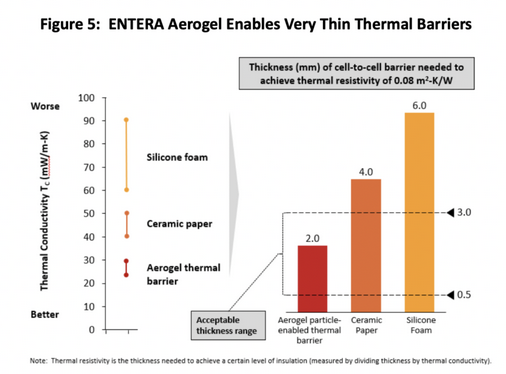

Aerogels are a high-performance alternative to conventional thermal insulation. Currently, these materials are used where space matters most. Usually two aspects are relevant in construction:

-

Where existing buildings require energetic renovation to improve energy efficiency, often little space is available for thermal insulation e.g. on the inner side of exterior walls, in wall cavities or beneath floors. Strongly limited space benefits from the highest possible performance of aerogels – to maximize energy efficiency.

-

For new building projects, the higher performance of aerogels enables slimmer wall construction. This conserves valuable useable space in the building. While using aerogels seems expensive at first, the use of these high-performance products pays off in many cases. The additional space the slimmer wall design creates leads to additional revenue that can cover the cost of the aerogel materials and more, which makes the decision on using aerogel materials economically attractive to investors.

But a third aspect is often overlooked: Aerogels also enable new possibilities in terms of building aesthetics, since much more lightweight building designs become possible. Construction no longer needs to be heavyweight to be energy efficient.