Last week, Marc and Dirk visited the SwissBau 2026 in Basel for several days.

It was great to meet lots of regional partners and contacts which normally are too far away from Osnabrück or Hamburg – such as Thomas Stahl and Julian Bäschlin from AeroPro Swiss GmbH and Sebastian von Stauffenberg from AGITEC AG. There was plenty of interesting aerogel-related gossip as usual.

AGITEC showed a strong presence with lots of #aerogel superinsulation solutions. As a highlight, they presented a new aerogel composite Agitherm with less than 13 mW/(m*K) – impressive! The translucent silica aerogel slab is always a nice eye-catcher as well (next to us in the photo). Of course, the aerogel-it team is always happy to see more aerogel presence in the Construction market.

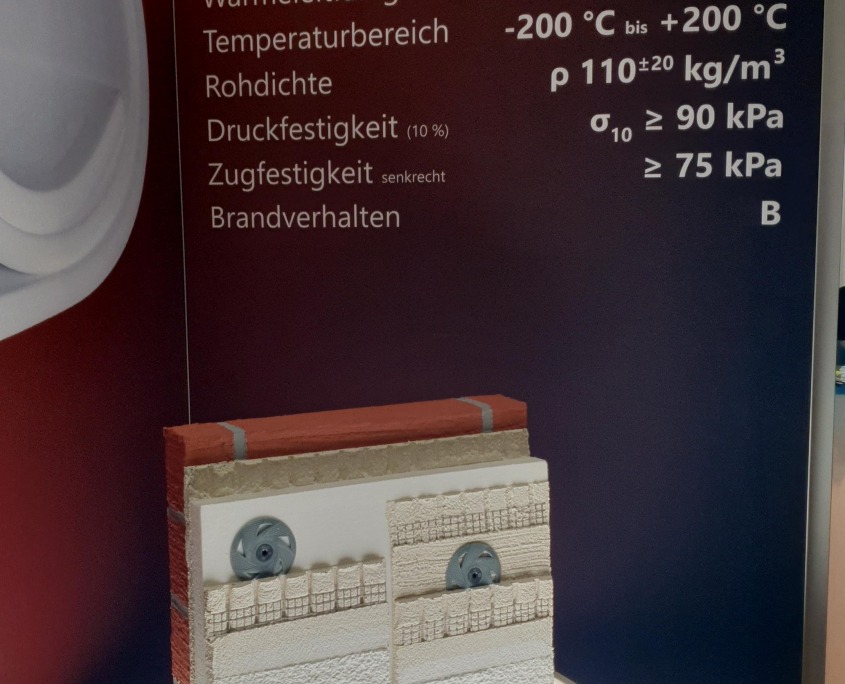

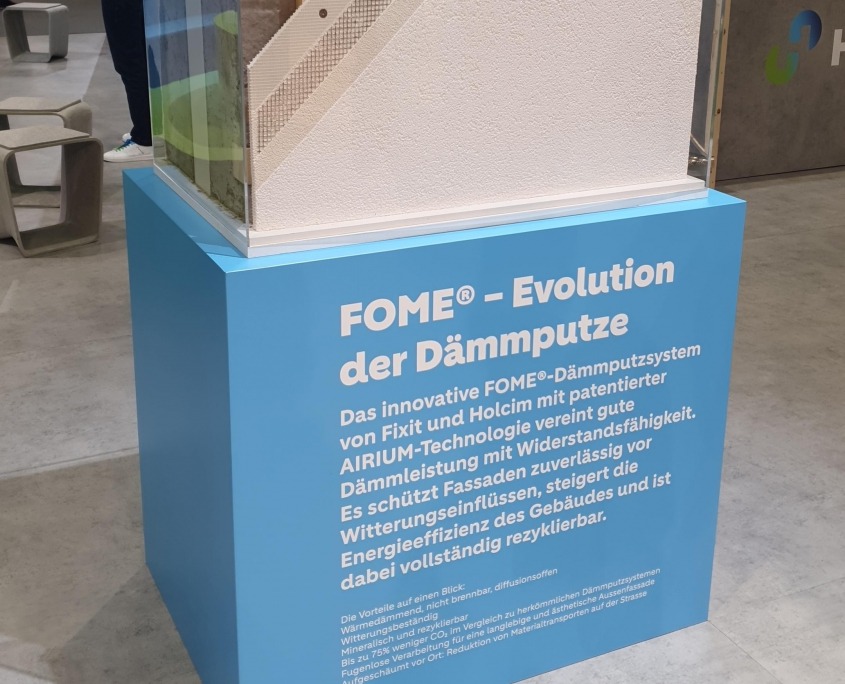

Otherwise interesting was a new inorganic foam product from Fixit AG and Holcim called Fome (like foam). There seem to be more developments in this area now which is nice. Marc and Dirk always have to think of the many years of hard pioneering work by the team around their former BASF colleague Dr. Frank Reuter on their product Cavipor.

Our friends from TROBART AG | Drywall thought NEW showed their MODUVO drywall which seems to be doing well.

In general, thermal insulation and energy efficiency seemed to be more present that for example at the last BAU 2025, where aerogel-it had shared a booth with va-Q-tec and presented vacuum-insulation panel prototypes based on our next-generation cellulose bioaerogel.

It is also true that we observe more aerogel activities in Switzerland than in Germany. However, aerogel render for energetic renovation seems to be growing strongly also in Germany so the next BAU 2027 should be interesting.

Aerogel the world!